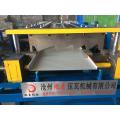

Iron Sheet aluminium Profile Panel Roof Forming Machine

Basic Info

Model No.: customized

Product Description

Iron Sheet aluminium Profile Panel Roof Forming Machine

Aluminium Profile Panel Roof Forming Machine maintenance for the life of color-coated steel tile roll forming machine use has a very important meaning, if you do not want your device to the problem of premature or should be replaced according to the method given below us maintain and maintenance, so not only can improve the life of your color steel roll forming machine will save all kinds of economic losses due to damage caused by color steel tile press for you.

Main parameters:

| 1 | Suitable to process | Color steel plate, galvanized sheet, aluminum coils and etc. |

| 2 | Width of the feeding material | 820/470/760 mm |

| 3 | Roller station | 16 rows or custom |

| 4 | Thickness of feeding material | 0.16-0.3mm |

| 5 | Power | 5.5kw |

| 7 | Productivity | 6-12m/min |

| 8 | Diameter of the roller | Φ70mm |

| 9 | Weight | About 4 T |

| 10 | Size | 8200*950*1000mm |

| 11 | Voltage | 380V 50Hz 3phases |

| 12 | Rolling material | 45# |

| 13 | Material of the cutting plate | Cr12 |

| 14 | Wall thickness of main forming machine | 14mm steel plate |

| 15 | Main forming machine body | 400 mm H steel |

| 16 | Control system | PLC control |

1. should be strictly in accordance with the requirements of the operating instructions to operate on the ban did not use machines or novice direct induction operation.

2. Each boot time to regularly check the adequacy of lubricating oil, check the oil if there is deterioration of the situation.

3. Color tile press equipment should be kept clean, regular color steel roll forming machine for dust protection.

4. Check the color steel tile press of a variety of connectors or fasteners are loose or dropped off, problems to deal with in a timely manner.

5. Regularly check the repair switch, insurance, handle, to ensure its reliable operation.

6. strict rules for safe working practices standard operating personnel, regular training basics of color steel tile press and prevent personal safety.

PACKAGING

1.Packaging Details:Nude,with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

2.Port:TIANJIN XINGANG PortLead .

3.Time: Shipped in 35 days after payment.

Usually the welding pipe cold roll forming machine can be packed into one 20' feet container or 40' feet container. We have good relationship with the shipping agent. Either you can find the shipping line at your side or we can help you.

ABOUT OUR COMPANY

Cangzhou Dixin Roll Forming Machine Co.,Ltd,Our company is the professional and leading manufacture,can manufacture ,design,installation and debug various roll forming machines and metal processing sheet equipments ,which produce metal roof wall panel,glazed roof tile , CZ steel purlin,floor desking,roof ridge cap,sandwich panel ,roof rtruss,shutter panel,shutter slat,door frame, guardrail ,and metal sheet uncoiler ,bending ,slitting,cutting,flattening,punching,crimpingl. especially can design machine according to customer's request.

MACHINE PARTS

OUR SERVICE

1.We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

2.we can send our engineer to your site and do the training for your worker. you just only bear the cost for our engineer's air ticket,visa,accommodation,food and transpotaion in your country.

3.You can send your worker to our factory. we will teach them how to operate the machine without training charges.

4.Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

Please contact Alice

Product Categories : Roof And Wall Panel Roll Forming Machine