Fire Protection Standard Type Aluminum Pipe Frames

Basic Info

Model No.: Standard or OEM

Product Description

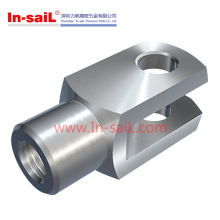

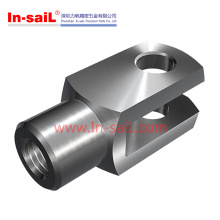

Model NO.: Standard or OEM Shape: Round Temper: T3-T8 Alloy: Alloy Alloying Ingredient: 6061 Polished Aluminum Profile: Chemical Polishing Series: Clevis/Joint/Bearing/Casters/Frame Surface Treatment: Anodizing, Polished, Powder Coating, etc Inspection: 100% QC Steps Inspect Before Shipment Export Markets: Global Specification: RoHS, SGS, ISO HS Code: 7318160000 Type: Window & Door Aluminium Profile, Decoration Aluminium Profile, Heat Sink Aluminium Profile, Glass Wall Aluminium Profile, Transport Aluminium Profile Grade: 5000 Series Window & Door Aluminium Profile: 70 Series Surface Finishing: Anodic Oxidation Certification: CE, ISO, RoHS Model No.: Automation Components Linking Technology Material: Brass/Stainless Steel/Al Alloy/Steel etc Design: OEM Services Provided Manufacture Processing: CNC Maching/Casting/Stamping/Forging/Injection Mol Trademark: In-sail or OEM Origin: Shenzhen, China 1. Material: Aluminium alloy, steel,etc.

2. Temper: T5, T6,etc

3. Quality standard: DIN, ISO,GB,etc

4. Surface treatment: Mill finish, anodized, powder coated, electrophoresis, sand balsting etc

5. Color avalilable: Silver, Any is available.

6. Packing details: PE bags+Cartons+Plywood pallet with Belt &Film;By customer's requirements.

7. Samples time: 3-5 days

8. Delivery: 5-15 Days for Mass Production.

9. Production Capacity: 5000MT/Month

10. MOQ: 5000pcs

11. Payment terms: T/T

12. Port: Guangzhou, Shenzhen,Shanghai;As per requested.

In-saiL is dedicated to manufacturing of precision components and the design, fabrication of engineering specialty fasteners and fastening solution development.

Manufacturing Capability

We have powerful manufacturing capability, automatic lathes, CNC lathes, CNC Machining centers, stamping machines and cold heading machines plus auxiliary equipment

like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

Automation Components

Available for a variety of sizes automation components,In-saiL provides solutions to suit any customer need.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum alloy, stainless steel components.

Production range: O.D. 0.5-15

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless steel Screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max. Contact us if you need more details on Frames. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Pipe Frames、Pipe Frames. If these products fail to match your need, please contact us and we would like to provide relevant information.

2. Temper: T5, T6,etc

3. Quality standard: DIN, ISO,GB,etc

4. Surface treatment: Mill finish, anodized, powder coated, electrophoresis, sand balsting etc

5. Color avalilable: Silver, Any is available.

6. Packing details: PE bags+Cartons+Plywood pallet with Belt &Film;By customer's requirements.

7. Samples time: 3-5 days

8. Delivery: 5-15 Days for Mass Production.

9. Production Capacity: 5000MT/Month

10. MOQ: 5000pcs

11. Payment terms: T/T

12. Port: Guangzhou, Shenzhen,Shanghai;As per requested.

In-saiL is dedicated to manufacturing of precision components and the design, fabrication of engineering specialty fasteners and fastening solution development.

Manufacturing Capability

We have powerful manufacturing capability, automatic lathes, CNC lathes, CNC Machining centers, stamping machines and cold heading machines plus auxiliary equipment

like milling machine, grinding machine, EDM and the cooperation of our partners, we are able to support every different components regardless of the prototyping or series production.

| Material | Brass,Stainless Steel,Carbon steel,Aluminum alloy,according to customer's requirement |

| Finish | Zn/Ni/Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting, powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max | |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Automation Components

Available for a variety of sizes automation components,In-saiL provides solutions to suit any customer need.

Auto Lathe Turning

The single shaft cam-base automatic lathes are capable of massive production of brass, aluminum alloy, stainless steel components.

Production range: O.D. 0.5-15

CNC Milling

4-axis and 5-axis machining centers are capable of complex structural parts.

Production range: 800x600

Screw Heading & Rolling

The screw production lines finish the cold heading and thread rolling for small carbon steel or stainless steel Screws.

Production range: M0.8-M6 or equivalent sized imperial screws

Stamping

Stamping machines perform the blanking, punching, blending, drawing. Currently we are working on simple stamping jobs.

Production range: 200T max. Contact us if you need more details on Frames. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Pipe Frames、Pipe Frames. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Automation Components

Other Products

Hot Products

ANSI ASME track boltT5 T10 T15 T20 T25 T30 T40 T35 drive torx screwStainless Steel Eye ScrewBulk Buy From China America Truck Hot Sale Grade 8.8/10.9 Wheel Hub Boltchina supplier high quality black finished steel square head boltManufacture Certificated ISO9001:2008 Popular In Europe U Bolt Wiht Good ServideHOT HOT HOT Track Bolt and Nut in Grade 8.8&10.9machine screwalibaba online shopping carbon steel yellow zinc plated T head boltChina Supplier Wire Rod, SAE1008 Steel Wire Rod With Good PriceChina supplier carbon steel double head thread stud bolthardware supplier carbon steel zinc plated hex socket screwalibaba hardware supplier mild steel zinc plated flange bolthardware supplier A193 B7 black oxide stud bolt with nutalibaba online supplier black zinc plated carbon steel carriage bolts304 Stainless Steel Bolt and Nut