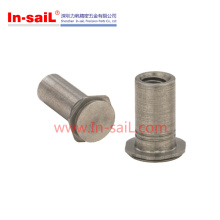

Barbed Insert Fastener for Furniture

Basic Info

Model No.: all kinds

Product Description

Model NO.: all kinds Type: Round Head Head Style: Round Grade: 8.8 Finish: Clean, Zinc Plated, Black Oxide or OEM Managet Systemmen: ISO9001:2008 Trademark: In-saiL Origin: Shenzhen, China Material: Stainless Steel Connection: Common Bolt Standard: DIN, ANSI, GB, JIS, GOST, BSW, OEM Tolearance: ISO 2768-M or OEM Thread: 6h, Unc, Unf, Whitworth or Find Certification: SGS, RoHS, Material Certication, Ppap Specification: SGS, Material certification HS Code: 7318160000 About Us:

Sandum/In-saiL offers a wide range of Self Tapping Threaded inserts for Aluminium, cast iron, plastics and NF metals. These available in sizes M2 to M30 and equivalent UNC, UNF and BSW threading. Self Tapping Threaded Insert is designed as a permanent fastener in materials which are of insufficient strength to sustain applied loads in threads tapped directly in to these materials or where thread wear occurs due to frequent assembly and disassembly. The Self Tapping Threaded Insert is a bushing with internal and external threads designed to tap its own threads and is driven into a drilled or cored hole. The thread cutting action is performed by the holes or by the slot on the pilot portion of the inserts.

Features & Benefits include:

Tough and durable due to their substantial wall thickness, their use can reduce the thread size required due to the insert's large effective shear surface. This could save material as well as reduce cost and weight.

They eliminate the need for close tolerance holes required for tapping into the base material, damaged tools and low productivity - they need no special installation tool nor the time consuming process associated with installing a wire thread insert. Holes do not need to be separately tapped as the groove will cut its own thread so long as the correct diameter tolerances for the material and the insert are adhered to

.

Contact us if you need more details on Threaded Insert. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Threaded Insert for Repair、Threaded Insert for Aluminium. If these products fail to match your need, please contact us and we would like to provide relevant information.

Sandum/In-saiL offers a wide range of Self Tapping Threaded inserts for Aluminium, cast iron, plastics and NF metals. These available in sizes M2 to M30 and equivalent UNC, UNF and BSW threading. Self Tapping Threaded Insert is designed as a permanent fastener in materials which are of insufficient strength to sustain applied loads in threads tapped directly in to these materials or where thread wear occurs due to frequent assembly and disassembly. The Self Tapping Threaded Insert is a bushing with internal and external threads designed to tap its own threads and is driven into a drilled or cored hole. The thread cutting action is performed by the holes or by the slot on the pilot portion of the inserts.

Features & Benefits include:

Tough and durable due to their substantial wall thickness, their use can reduce the thread size required due to the insert's large effective shear surface. This could save material as well as reduce cost and weight.

They eliminate the need for close tolerance holes required for tapping into the base material, damaged tools and low productivity - they need no special installation tool nor the time consuming process associated with installing a wire thread insert. Holes do not need to be separately tapped as the groove will cut its own thread so long as the correct diameter tolerances for the material and the insert are adhered to

.

| Material | Aluminum alloy,Brass,Stainless Steel,Carbon steel,according to customer's requirement |

| Finish | Milled /Tin plating, copper-plating,hot-dip galvanizing, black oxide coating,red anodized,black anodized,painting, powdering,rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Testing Equipment | CMM,Projector,Pull Tester,Automatic Optic Inspector,Projecting apparatus Salt Spray Test, Durometer, and Coating Analyzer,Tensile Machine |

| Managet Systemmen | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max | |

| Lead Time | 5-15 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Warranty | Replacement at all our cost for rejected products |

Contact us if you need more details on Threaded Insert. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Threaded Insert for Repair、Threaded Insert for Aluminium. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Threaded Inserts for Wood

Premium Related Products

Other Products

Hot Products

ANSI ASME track boltT5 T10 T15 T20 T25 T30 T40 T35 drive torx screwStainless Steel Eye ScrewBulk Buy From China America Truck Hot Sale Grade 8.8/10.9 Wheel Hub Boltchina supplier high quality black finished steel square head boltManufacture Certificated ISO9001:2008 Popular In Europe U Bolt Wiht Good ServideHOT HOT HOT Track Bolt and Nut in Grade 8.8&10.9machine screwalibaba online shopping carbon steel yellow zinc plated T head boltChina Supplier Wire Rod, SAE1008 Steel Wire Rod With Good PriceChina supplier carbon steel double head thread stud bolthardware supplier carbon steel zinc plated hex socket screwalibaba hardware supplier mild steel zinc plated flange bolthardware supplier A193 B7 black oxide stud bolt with nutalibaba online supplier black zinc plated carbon steel carriage bolts304 Stainless Steel Bolt and Nut